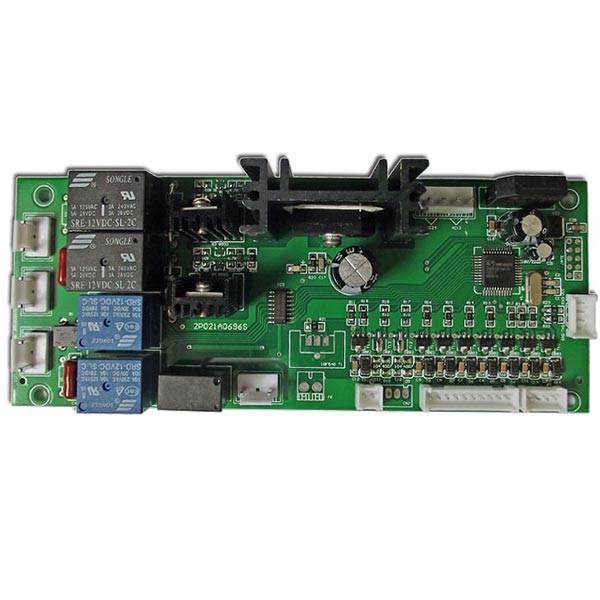

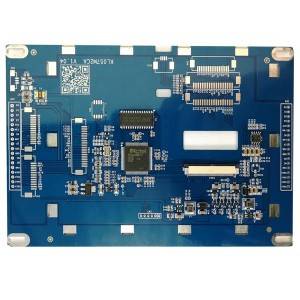

Board Electronics Assembly Services

Basic Information:

| Metal Coating: HASL lead free | Mode of Production: SMT+ | Layers: 4 Layer PCB |

| Base Material: High Tg FR-4 | Certification: SGS, ISO, RoHS | MOQ: No MOQ |

| Solder Types: Lead-Free (RoHS Compliant) | One-Stop Services: PCB Manufacturing And Turnkey PCB Assembly | Testing: 100% AOI / Visual Test |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly Service, PCB Assembly Process, PCB Manufacturers, Printed Circuit Board Assembly Companies

What Does PCB Assembly Mean?

Printed Circuit Board Assembly, also known as PCBA, is the process of mounting various electronic components on the PCB. The circuit board before assembling the electronic components is called PCB. After the electronic components are soldered, the board is called a printed circuit board assembly (PCBA). The traces or conductive pathways engraved in the laminated copper sheets of PCBs are used within a non-conductive substrate in order to form the assembly. Attaching the electronic components with the PCBs is the concluding action before using the fully operational electronic device.

PCBFuture can provide turnkey service from PCB manufacturing to PCB assembling, testing to housing. PCBFuture has become a very stable and healthy company. Our achievements have been fully affirmed and supported by governments at all levels. As the leading brand, PCBFuture is going to shoulder great social responsibility and operation mission, fully participate in international competition, and strive to become the world-class PCB producter.

Why choose?

1. We have many years of rich experience in PCB production and assembly. There are very professional technicians and operators, with very advanced PCB assembly technology, they are the guarantee of product quality. On this basis, we can also provide you with cheaper, better quality products.

2. Whether you need prototype PCB assembly or batch assembly, PCBFuture can accommodate up to 1 to 10,000 single pieces, and has a dedicated assembly line to meet the needs of high-volume and low-volume.

3. Get the entire PCBA produced in 15 working days or less from order confirmation to dispatch, including purchase of parts. However, if you need faster delivery time, we can do it, but you may need to pay an additional premium.

We can provide below services:

PCB Manufacturing

Mid volume PCB assembly

Turnkey Services

Quick-Turn assembly

Prototype, Small or Large Batch

PCB Assembly Cost

PCB assembly cost has its standard calculation method, which includes cost of PCB fabrication, component, SMT/DIP assembly, testing and logistics. For a small number of prototype orders, engineering costs will be charged. Flying probe or frame test for PCB manufacturing, stencil and regular 5% loss of components during PCB board assembly process should be also concerned. For PCB assembly testing, it depends on the test plan and duration of completing a board.

What any other information should be offered except for the file?

a) Base material

b) Board thickness

c) Copper thickness

d) Surface treatment

e) Color of solder mask and silkscreen printing

f) Quantity

g) Other special requirements

PCBFuture is a supplier of PCB and associated products & services to the electronics design and fabrication industry. Today, all of electronic producers realize that no matter what and where their customers are, they are competing in a global market place. In order to be competitive, all manufacturers need to find the competitive suppliers. If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.