What is Printed Circuit Board Assembly?

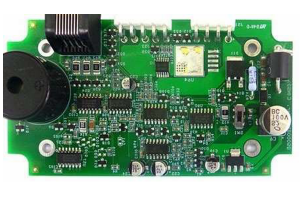

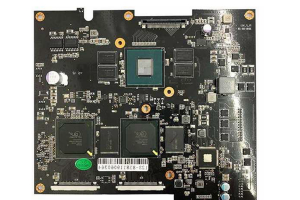

Printed Circuit Board Assembly is the process of connecting electronic components with wiring of printed circuit board. The wiring or conducting path engraved on the laminated copper plate of PCB is used in the non-conductive substrate to form a component. Attaching the electronic components with the printed circuit boards is the concluding action before using the fully operational electronic device.

Printed circuit board assembly requires careful assembly, especially attention to detail and absolute accuracy, which will determine the successful operation of electronic equipment. At present, the electronic machine and PCB can be assembled by surface mount assembly (SMT), plated through hole technology (PTH) and electro mechanical assembly.

Why choose our printed circuit board assembly service?

1. PCBFuture has a mature and effective components procurement systems serve the turn-key of PCB assembly with low cost, has a professional team responsible for our customer's PCB components procurement and management.

2. We offer Surface Mount (SMT), Thru-Hole (THT) and hybrid of both. We also offer single or double-sided placement.

3. We have the ability to organize incoming raw materials, process control, and fine testing, and can provide you with the best PCB assembly services from small batch to mass production. During the PCB installation process, if there are defects related to PCB manufacturing, our engineers will report a DFM report.

4. We will send you the BOM price by email within 24 hours.

5. With our BGA pressure welding service, we can safely remove the misplaced BGA, pressure-weld it, and then put it back on the PCB correctly. It is cost-effective.

6. PCBFuture has various equipment from automatic placement equipment, large wave soldering furnaces to manual insertion and soldering stations. These diversified functions enable us to meet the batch requirements from fast-turnover prototypes to on-time delivery of mass production runs. Conformal coatings can also be used to meet environmental requirements.

7. Our quality management plan is a cornerstone of our operation, and our process complies with IPC 610 and ISO 9002 standards for through-hole, hybrid and surface mount PCBs. We have full-time engineers to assist you in design and layout, and provide a complete component procurement and inventory management plan. When you choose our PCB assembly service, you can guarantee the consistent and timely delivery of valuable circuit board components.

What's the service we can offer?

2-32L through-hole board & HDI

High frequency board

Backplane

Embedded resistance board

Semiconductor test products

Heavy copper power board

2-6L metal base board

2-8L flex board & Rigid-flex board

Finished product testing

Box building services

Sourcing of components and complete PCB assembly

We also provide services related to PCB repair and rework and electronic circuit testing. Our equipment and assembly process are in compliance with IPC, MIL-Spec, RoHS 5 and 6 standards

How to get quick printed circuit board assembly quotation before order?

You should send the Gerber file, BOM list and PCB specification to get quick printed circuit board assembly quotation before order.

PCBFuture is Professional PCBA & PCB manufacturer from China. We are mainly offers high-precision single-side, double-side multi-layer PCB, LED aluminum PCB, flexible PCB, components procurement PCB Manufacturing and PCB Assembly service. PCBFuture has introduced advanced equipment and strengthen & sound management system. Meanwhile, We has passed the certificates of international quality system as ISO 9001:2008. We have material inventory complete and worldwide suppliers.

With over 10 years as an industry leader, PCBFuture is one of the most experienced PCB manufacturers in the China. We're proud to manufacture high-quality products, and provide a safe and prosperous workplace for our 200 employees.

PCBFuture has experienced professional and technical R & D technology team, young and professional sales and customer service teams, experienced and professional procurement team and assembly testing team, which make sure the products quality of the pass rate, on-time delivery rate of customer orders.

As a partner of leading PCB manufacturing and PCB assembly (PCBA) services, PCBFuture strives to have more than 10 years of engineering experience in electronic manufacturing services (EMS) to provide support for more customers. We are determined to become a leader in special electronic circuit interconnection services.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.

FQA:

No. We have high quality standards and will only assemble boards ordered thru PCBFuture. Part of what makes us unique is that we fabricate and assemble in one continuous operation with consistent quality and expedited turn-time.

Yes. PCBFuture has no minimum order quantity requirements and can assemble even one board. For more information please check our prototype assembly page.

Yes we can do partial PCB assembly for both kitted/consigned orders or for turnkey.

Component footprint should be made per manufacture recommendations for pad size and mask clearance. All BGA type devices are required to have all vias under component tented with soldermask.

We return all unused parts to the customer whether kitted/consigned or turnkey.

We will provide you pricing for PCB assembly. The PCB assembly pricing includes tooling, solder stencil and assembly labor for loading the components. Our turn-key quotes also show component pricing as indicated.

Yes.

Assembly builds to IPC-A-610 current rev Class 2. Class 3 and J-Std-001 are available with prior review.

PCB’s are required to have a format with breakaway rails of 0.5” on at least 2 opposing sides. If rails are not present we can build individual boards provided the following criteria is met: 1-up PCB size is 2”x2” (51mmx51mm) or greater, each 1-up PCB must have fiducials, fiducials must be a minimum of 0.118” (3.0 mm) from the edge of the PCB, no component can be closer than 0.196” (5.0mm) from the edge of the PCB.

If you encounter any problems after receiving the board you loaded, please contact us immediately. After determining the root cause of the problem, we will evaluate the problem and perform appropriate repair/rework or refurbishment. For any return, we will issue you an RMA number.