What is circuit board assembly?

The circuit board assembly refers to assemble the bare PCB with active and passive electronic components, such as resistors, SMD capacitors, transistors, transformers, diodes, ICs, etc. These electronic components can be through-hole components or SMT SMD components (surface mount technology)).

Circuit board assembly or soldering of electronic components can be done by automatic soldering techniques such as wave soldering (for through-hole components) or reflow soldering (for SMD components), or by manual soldering. Once all the electronic components are assembled or soldered to the bare PCB, it is called circuit board assembly.

Why choose our circuit-board-assembly service?

PCBFuture main customers come from medium-sized manufacturers in the fields of consumer electronics, digital products, wireless telecommunications, industrial management and automation, medical treatment, etc. Our solid customer base provides a strong impetus for the development of the company in the future.

1.Quick Turn prototype and mass production PCB

We dedicated in manufacturing 1-28layer quick turn, prototype and mass production high precision PCBs with the principle of “the Best quality, lowest price and fastest delivery time”

2.Strong OEM manufacturing capabilities

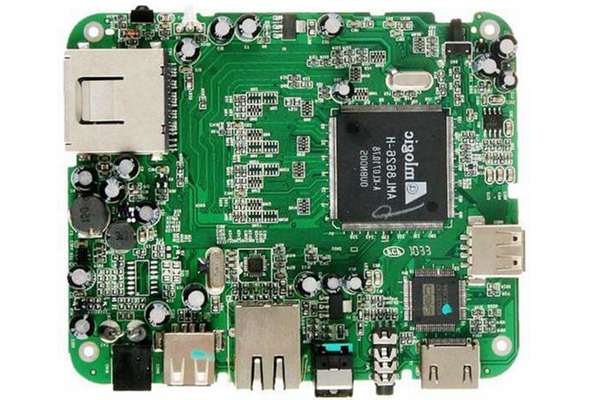

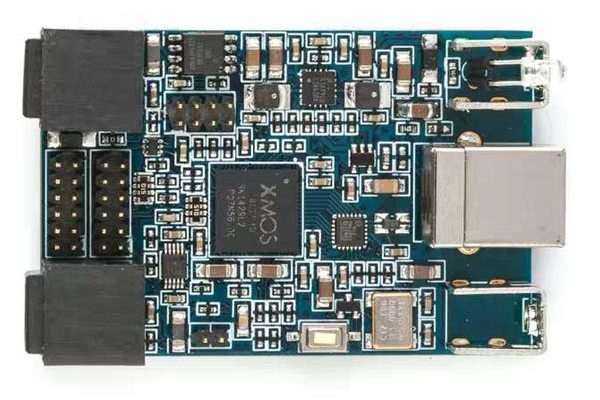

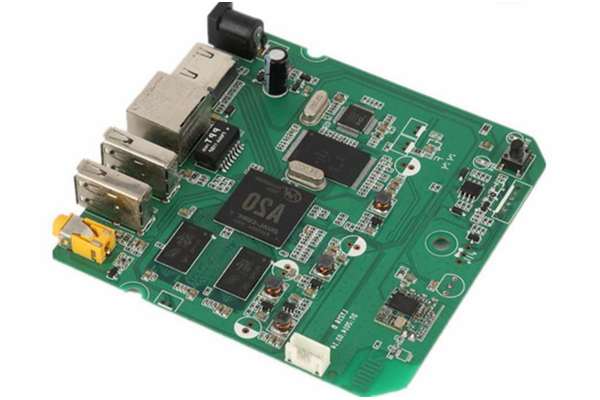

our manufacturing facilities include clean workshops and four advanced SMT lines. Our placement precision can reach chip +0.1MM on integrated circuit parts, which means we can handle almost all kinds of integrated circuits, such as SO, SOP, SOJ, TSOP, TSSOP, QFP and BGA. In addition, we can provide 0201 chip placement through-hole components assembly and finished products manufacturing.

3.Committed to improving product quality

We are committed to improving the quality of PCBs. Our operation have passed ISO 9001:2000-certified, and our products have obtained CE and RoHS marks. In addition, we are applying for QS9000, SA8000 certification.

4. Normally 1 ~5 days for only PCB assembly; 10 ~25 days for turnkey PCB assembly.

What's the service that PCBFuture we can provide:

1. Surface Mount Technology (SMT)

2. Thru-Hole Technology

3. Lead Free PCB fabrication and assembly

4. Consignment PCB Assembly

5. Mixed Technology Assembly

6. BGA Assembly

8. Functional testing

9. Package and logistics & after- sales service

10. Components sourcing

11. X-ray AOI testing

12. PCB supply and layout

Some basic components needed for circuit-board-assembly:

Printed circuit board: It is the main requirement of the assembly process.

Basic electronic components: You need all electronic components such as transistors, diodes and resistors.

Welding material: The material includes solder paste, solder bar and solder wire. You also need solder and solder balls. Flux is another important soldering material.

Welding equipment: This material includes wave soldering machine and soldering station. You also need all the necessary SMT and THT equipment.

Inspection and test equipment: Test materials are essential for inspecting the workability and reliability of circuit board assembly.

Over the years, PCBFuture has accumulated a large number of PCB manufacturing, Production and debugging experience, and relying on these experiences, provide major scientific research institutes and large and medium-sized enterprise customers with a one-stop design, welding, and debugging of high-efficiency and high-reliability multi-layer printed boards from samples to batches This type of service is widely used in various industries such as communications, aerospace and aviation, IT, medical treatment, environment, electric power, and precision testing instruments.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.

FQA:

Yes. We do offer RoHS-compliant assemblies.

Yes. We do offer different types of testing and inspection services.

All PCBs are tested and inspected at each stage of assembly. PCB components are tested in the following types:

X-ray test: this test is performed as part of the standard assembly process for ball grid array (BGA), Quad leadless (QFN) PCB, etc.

Function test: here, we perform function check on PCB. This is to determine if the PCB works according to the customer specified requirements.

In-Circuit Testing: as the name suggests, this test is performed to check for faulty or short circuit connectors.

We conduct an in-depth inspection of components and their functioning on the assembled PCB. They are subjected to Automated Optical Inspection (AOI). This helps identify, polarity, solder paste, 0201 components, and if any components are missing.

At PCBFuture, we conduct a detailed check on your Bill of Material (BOM) and share the list of components that are already available with us. Most of the times, these components are free parts or low price parts. In addition to this, our experts will also help you reduce the cost of manufacturing by utilizing our free cost parts. The final decision always lies with you.

Yes. We do offer aftersales support on all PCB assemblies. If there is an issue in our workmanship, our experts will evaluate them and repair, remake, or rework on them by determining the root cause of the problem. For any assistance, please contact us.

As discussed before, each order must be neatly packaged with its all required components. If you are sending mutual parts for both the circuit boards, please ensure to provide 5% extra parts for each assembly. These parts must be clearly marked with a sticker denoting the ones that are common for both builds.

Yes. You can place multiple orders at the same time.

You can provide the components in a tray or bag that is clearly marked with the part numbers from your BOM. Please take care to protect the components during the transit. You can contact our experts to understand how the components can be supplied.

Assembly lead times quoted to the client exclude the procurement lead time. The lead times for the circuit board assembly order entirely depend on the time required to source the part. The assembly begins only after all the components are available in the inventory.