What is Prototype PCB assembly?

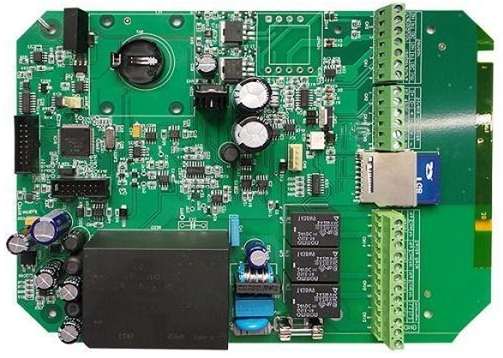

Prototype PCB assembly means trial production of printed circuit board before mass production, it mainly use before small batch trial production process which electronic engineers finished product design and PCB layout.

Prototype PCB assembly have many names. The names you usually hear are: surface-mount technology (SMT) PCB prototypes, PCBA prototype assembly, PCB sample assembly, etc. Prototype PCB assembly refers to a rapid prototyping PCB assembly used to test the function of new electronic design. These will help the quality assurance, verifying and test product, finding errors, and updating the design. Normally, before mass production, an electronic project will need 2-3 iterations of prototype PCB assembly to ensure everything is working fine.

PCBFuture engineers quickly and cost-effectively assemble its electronic prototypes throughout the design verification process. In order to ensure the product design meets the requirements, we usually recommend using 5pcs or 10pcs for prototype assembly test.

Why we need prototype PCB assembly service?

In order to make sure a new electronic products are perfect before launch to market, we will need to test the prototypes before mass production. PCB manufacturing and PCB assembly are necessary process for prototype turnkey PCB production. Prototype PCB assembly is for functional test purpose, so the engineers could optimal design and fix some bugs. Sometimes it may will need 2-3 times, so find a reliable electronic assembly manufacturer is very important.

The reason for why we need prototype PCB assembly service, because you need to quickly evaluate the work effect of PCB design. You have to complete the assembly process to do this. PCBFuture can do your PCB prototype assembly in-house. Therefore, you can quickly understand how the assembled pcb prototype works. We can provide customized PCB prototype assembly services, as well as our high-quality manufacturing and component sourcing. We will use your unique PCB design to prepare for the assembly process and conduct comprehensive testing to ensure that they meet your precise performance requirements. We can provide a complete set of PCB prototype assembly in one-stop mode, it will saving you more time, money and trouble.

What is our Prototype PCB Assembly service?

PCBFuture are good at printed wiring assembly service. With our professional soldering technicians, SMT handling Engineers and component sourcing specialists we can provide an low cost PCB assembly, highly flexible assembly process with quick turn service. Below are list of some services we provide:

-

One-stop PCB manufacturing and assembly

-

Cheap PCB assembly

-

Prototype PCB assembly services (quantities from 1 to 25 boards)

-

Turnkey Quick turn PCB assembly

-

Single or double sided SMT assembling

-

Thru-hole Assembly, EMS PCB, and mixed prototype assembly

-

PCBA Function test

-

Personalized and standardized service

Why customers like our prototype PCB assembly service?

1. PCBFuture can get your PCB and PCBA prototype to you fastest in a week or days, normally our lead time are 3 weeks, not months. All our work will help you to get your PCB assembly prototypes then test faster, which means you can sell your electronic products faster.

2. We have high availability of components, and establish long term and cooperative relationship with authorized well know components distributors and manufacturers. What’s more, we have specially assigned engineer responsible for each project and could provide with flexible assembly options to our customers too.

3. Fast prototype PCB assembly service can save the prototype and test cycle. And it help you make your products comes to the market faster than your competitors, also reduce the cost too.The world runs more fast and ever before. Often the company that is the first to market gets the lion’s share of the profits. At PCBFuture, we want accompany with you and provide with fast PCB prototype manufacturing and electronic board assembly service.

4. PCBFuture provides a variety of ways to reduce your PCB prototype assembly costs. We work with many well-known component suppliers to enable us to purchase the most affordable components for your project with good quality. We also offer many cost-effective packaging options, as well as highly advanced technology to choose one, which you can save more money.

How to get quick prototype PCB assembly cost before placing order?

If you need a prototype PCB assembly quote, please send us following files to sales@pcbfuture.com , you will get full quote in 48 hours (Normally in 24 hours).

Gerber files

Bill of Materials (BOM List)

Quantities and other special tech requirements if need

PCBFuture is qualified to manage the complete turnkey PCB process, which includes the sourcing of all components (PCB and parts), PCB assembly, quality control, functional test and delivery.

FQA For Prototype PCB Assembly :

Yes, we can.

Normally, we will need about 3-4 weeks lead time

We offer the PCB fabrication, parts sourcing and PCB assembly in a continuous and smooth manner to save our customer's time and money.

If you have your own PCB products, you just need our PCB assembly services, and we can still be perfect to do it, you just need to send us your board.

Yes. For more information please check our prototype PCB assembly page.

We will provide you pricing for PCB assembly. The PCB assembly pricing includes tooling, solder stencil and assembly labor for loading the components. Our turn-key quotes also show component pricing as indicated. We do not charge setup fees or NRE\'s for assembly.

We need Gerber files, Centroid data and BOM for your PCBA orders. As have already placed your PCB order with us, actually you only need to send the latter two if your PCB Gerber files have included the layers of silkscreen, copper track and solder paste. If your PCB Gerber files are missing any of the above-mentioned three layers, please resend them, as this is the minimum request for PCBA. For the best possible result, please also send assembly drawings, instructions and photos to us to avoid any ambiguous and even mistaken placement of parts, though these are not required by most of the assemblers.

Yes, We can handle lead-free builds. But we also offer leaded PCBA services.

Yes. This practice is called partial Turn-key. You can supply some parts, and we source the rest of the parts on your behalf. We will ask for your approval for anything that is not sure at our side. In case parts crossing or substitution is needed, we will again ask for your final approval.