What is PCB manufacturing and assembly?

PCB manufacturing and assembly is that a vendor will provide PCB manufacturing services, and assemble the PCB by soldering the electronic components onto the circuit board itself.

At PCBFuture, we offer both printed circuit board assembly services and printed circuit board manufacturing services. We ensure that you deliver the schedule on time and get the best price. All PCBs meet the high standard established by IPC 600. As PCBFuture is the IPC certified trainer of IPC a-610, we know the importance of bare board quality and the factors that can improve PCB assembly labor.

What's the difference of PCB manufacturing and PCB Assembly?

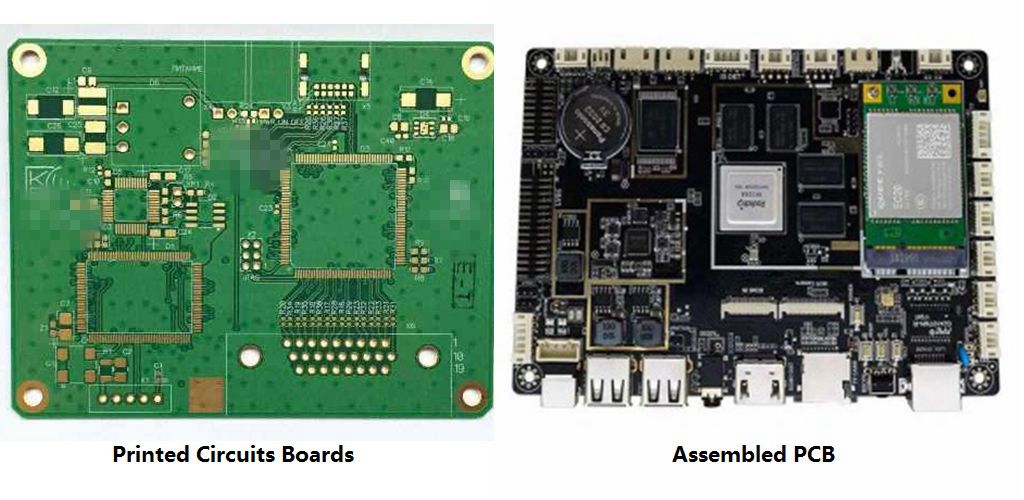

PCB (printed circuit board) is a board that uses conductive traces, pads, and other features etched from copper foil laminated on a non-conductive substrate to electrically connect electronic components. PCB can be single-sided (one copper layer), double-sided (two copper layers) or multilayer (outer layer and inner layer). The conductors on different layers are connected by through holes (plated through holes). Multilayer PCB allows higher component density and design complexity.

PCBA (printed circuit board assembly) is a kind of PCB that all components and parts are welded and installed on PCB. Now it can complete the electronic function of its design.

Do PCBFuture provide PCB manufacturing and assembly service?

PCBFuture can provide PCB manufacturing and assembly service. We have customers from different industries in terms of cost-effectiveness, quality, delivery and any other requirements. From PCB layout to PCB prototyping, mass manufacturing, and then PCB assembly, electronic box assembly services, our printed circuit boards are widely used in robotics, medical, automotive, communications, industrial and consumer electronics products.

We are engaged in the following businesses: flexible PCB, custom PCB, prototype PCB, turnkey PCB assembly, quick turn pcb assembly, electronic PCB assembly, small batch PCB assembly, etc.

PCBFuture have strong quality control system and all the certificates such as TS16949, UL, RoHS, CE, ISO, etc.. For PCB, we have Flying Probe Test and E-Testing. For PCBA, we have IQC, AOI, Function Test, QA. These are basic but very important factors for PCB industry.

As the most popular PCB manufacturing and assembly company in China, we have been providing full-spec electronic manufacturing solutions for 13 years to meet the needs of the Chinese market.

Why choose PCBFuture for your PCB manufacturing and assembly service?

1. Extremely high precision and precision-Our prototypes are excellent in accuracy and can meet customer specifications. This is because we take quality and details seriously.

2. Fast turnaround-we understand the value of customer time. Therefore, we strive to manufacture your prototype at a reasonable speed. Therefore, our rapid prototype PCB assembly service can shorten your waiting time from a few weeks to a few minutes.

3. Extremely low prices-we have a comprehensive approach to help you keep prices low and affordable. Therefore, we will complete your project with a reasonable budget.

4. Error correction-Our PCB prototype is very important to find defects, so it can avoid major failures later. Eliminating these defects as early as possible can save you a lot of time and cost

5. Online quick quotation-you can request PCB prototypes. You only need to submit the PCB design and receive the results.

6. Sample testing before full production – We allow you to test prototype boards and confirm whether they work as required.

The service we can provide:

1. Surface finishing: HASL Lead or Lead free, ENIG, Im Silver, OSP, Gold plated, etc

2. Single and double sided SMT/SMD. THT (through hole technology assembly). SMT & through hole assembly.

3. Inspection:

Visual inspection: general quality check.

FAI: full quality check applied to the first PCB to pass through all stages of production.

X-ray Inspection: checks for BGAs, QFN and bare circuit boards.

AOI Testing: checks for solder paste, 0201 components, missing components and polarity.

3D AOI Testing: checks for missing and misplaced SMT components in three dimensions.

3D SPI Testing: measures the precise volume of solder paste for SMT assembly.

ICT (In-Circuit Test).

Functional test (Following your test procedures).

Since PCBFuture established, we have co-operated with many companies at home and abroad with the idea of the quality first and client is god which have achieved high popularity. We has earned the trust and support of companies from over 40 countries with competitive prices, good quality products and excellent service.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.

FQA for PCB manufacturing and assembly

Yes, we can perform X-ray tests after assembly for parts like BGA.

We purchase all our components from reputable agents like DigiKey and Mouser. As such, we can guarantee the quality of the parts we use. We also have a quality control department that verifies the quality of all parts before they are incorporated into our products.

For each side having SMT or through-hole components that we will be populating:

1. Copper - for verification of pad location and scaling.

2. Paste - for stencil generation.

3. Silk - for reference designator location and rotation verification.

We work very hard to make sure all your PCB orders get shipped on time. There are occasions, however, when the freight carriers have delays and/or make shipment errors. We regret when this happens but we cannot be responsible for delays by these carriers.

We order to your exact bill of material ordering 5% or 5 extra for most components. Occasionally we are faced with minimum / multiple orders where extra components must be purchased. These parts are addressed, and approval received from our customer prior to ordering.

We provide PCB Assembly capabilities including smt and through-hole, double sided smt assembly, minor pcb repair, cable and harness assembly and more.

Yes, we offer a RoHS compliant assembly.

We offer quick turn PCB Manufacturing Services for PCB Layout, PCB Assembly, PCB Fabrication, PCB Prototype, Electro-Mechanical Assembly, PCB Box Builds, and more.

We provide IPC and ISO standard PCB Assembly.

There is an array of factors that directly impact the cost of PCB Assembly including technology used, single or double sided board, number of placements, coating, testing, shipping requirements, and more.