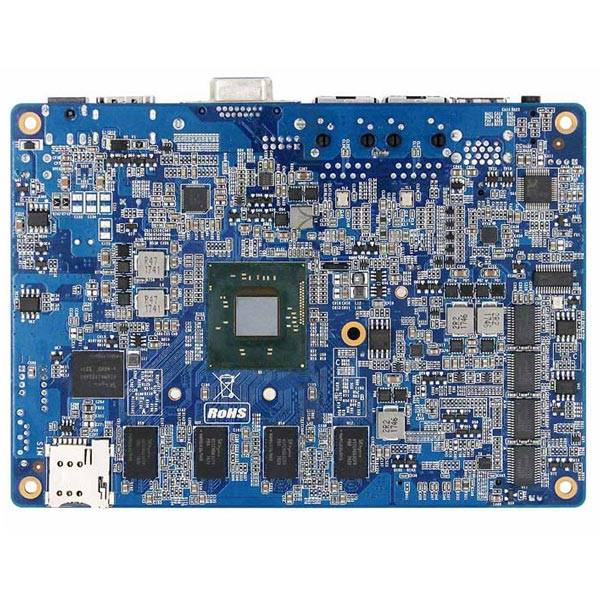

Turnkey PCB Electronic Assembly

Basic Information:

| Metal Coating: HASL Lead free | Mode of Production: SMT+ | Layers: 8 Layer PCB |

| Base Material: High Tg 170 FR-4 | Certification: SGS, ISO, RoHS | MOQ: No MOQ |

| Solder Types: RoHS Compliant | One-Stop Services: PCB Manufacturing And Turnkey PCB Assembly | Testing: 100% AOI / X-ray / Visual Test |

| Tehnology Support: Free DFM (Design For Manufacturing) Check | Types Of Assemblies: SMT, THD, DIP, Mixed Technology PCBA | Standard: IPC-a-610d |

PCB and PCBA Quick Turn PCB Assembly

Keywords: PCB Assembly, PCB fabrication, Requirements, PCB Assembly Manufacturers, Cheap PCB Assembly, Printed Circuit Board Assembly Companies

PCBFuture has been involved in PCB manufacturing. Over the years, we have been customer centric and deliver high quality multilayer high-speed PCB designs, taking into consideration of real-world manufacturing and test requirements.

At PCBFuture , we strive to work hand in hand with our customers. From prototyping to full-scale production, we are an extension of customer capabilities. We are constantly enhancing our quality programs and process to meet or exceed our customer’s requirements on a continuous basis.

PCBFuture is committed to implementing a quality management system so that its products and services always meet the requirements of our customers.

Why our PCB Assembly and PCB manufacturing service?

Our quality policy is to provide quality products and services to meet customers’ requirements and expectations by Price, Quality, Timely delivery and Service.

We support 24-hour online quote and urgent 12-hour service for PCB prototype. Specializing in the production of single-sided PCB, double-sided PCB, multilayer PCB, aluminum PCB and flexible PCB.

We are committed to meeting the needs of our customers from different industries in term of quality, delivery, cost-effectiveness and PCB solution. Also provide special customized service. Finally, PCBFuture customize PCB according to your budget to save your time to win the market.

We can provide below services:

Components sourcing

single-sided PCB

double-sided PCB

multi-layer PCB

Testing and programming

Quick turn PCB assembly

Turnkey PCB assembly

Low volume PCB assembly

Mid volume PCB assembly

Applications of Printed Circuit Boards:

1. Lighting Applications

LEDs with aluminum-based PCB are very desirable for a number of applications and industries.

2. Consumer Electronics

Consumer electronics are the devices we use daily, such as smartphones or computers. Even the newest models of refrigerators often include electronic components.

3. Medical equipment

For medical applications, a small package is needed to meet the size requirements for an implant or emergency room monitor. Therefore, medical PCB tend to be specialty high-density interconnect PCBs, also referred to as HDI PCBs. Medical PCB may also be made with flexible base materials, allowing PCB to flex during use, which is essential for both internal and external medical equipment.

4. Industrial Applications

5. Automotive Applications

6. Aerospace Applications

Precautions for the manufacture of high-frequency circuit boards:

1. The impedance control is strict, the relative line width control is very strict, and the general tolerance is about 2%.

2. Due to the use of special plates, the adhesion of PTH copper deposits is not high. Generally, plasma treatment equipment is required to roughen the through holes and the surface to increase the adhesion of PTH copper and solder mask ink.

3. Don’t grind the plate before welding resistance, otherwise the adhesion will be very poor, and can only be coarsened with micro-corrosive powder.

4. Most of the sheets are PTFE materials. There will be many rough edges when they are formed by ordinary milling cutters, which need special milling cutters.

5. The high frequency circuit board is a special circuit board with high electromagnetic frequency. Generally speaking, high frequency can be defined as frequency above 1 GHz.

Its physical properties, accuracy and technical parameters are very demanding. It is often used in automobile anti-collision system, satellite system, radio system and other fields.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.