When a customer submits a PCB proofing order, what matters need to be explained to the PCB proofing manufacturer?

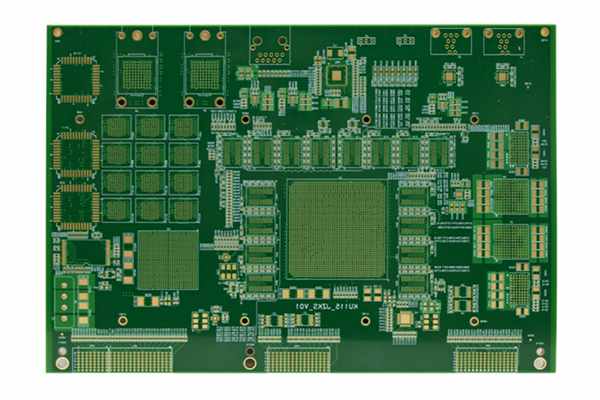

1. Materials: explain what kind of materials are used for PCB proofing. The most common is FR4, and the main material is epoxy resin peeling fiber cloth board.

2. board layer: Indicate how many layers to make.

3. Solder mask color: there are many colors, which can be selected according to their own requirements, generally green.

4. Silk screen color: the font and border color of silk screen on PCB board are generally white.

5. Copper thickness: the thickness of copper is generally calculated scientifically according to the PCB circuit current. The thicker the better, but the cost will be higher.

6. Whether the vias are covered with solder mask: Over soldering is to insulate the vias, otherwise the vias are not insulated.

7. Surface coating: tin spraying and gold plating.

8. Quantity: The number of PCB proofing should be clearly stated.

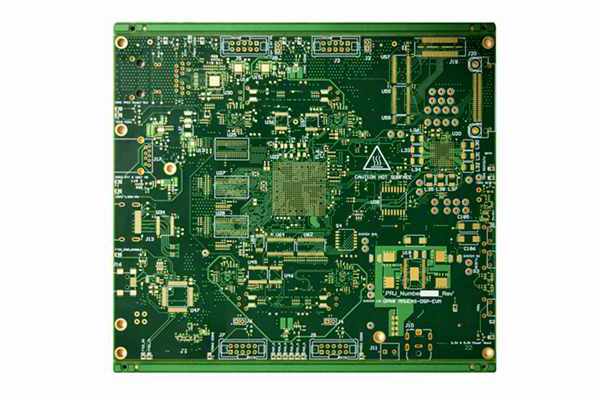

PCBFuture has build our good reputation in the full turnkey PCB assembly service industry for prototype PCB assembly and low volume, mid volume PCB assembly. What our customers need to do is send the PCB design files and requirements to us, and we can take care of the rest of work. We are fully capable of offering unbeatable turnkey PCB services but keeping total cost within your budget.

PCBFuture has build our good reputation in the full turnkey PCB assembly service industry for prototype PCB assembly and low volume, mid volume PCB assembly. What our customers need to do is send the PCB design files and requirements to us, and we can take care of the rest of work. We are fully capable of offering unbeatable turnkey PCB services but keeping total cost within your budget.

If you looking for a ideal Turnkey PCB assembly manufacturer, please send your BOM files and PCB files to sales@pcbfuture.com. All your files are highly confidential. We will send you an accurate quote with lead time in 48 hours.

Post time: Dec-05-2022