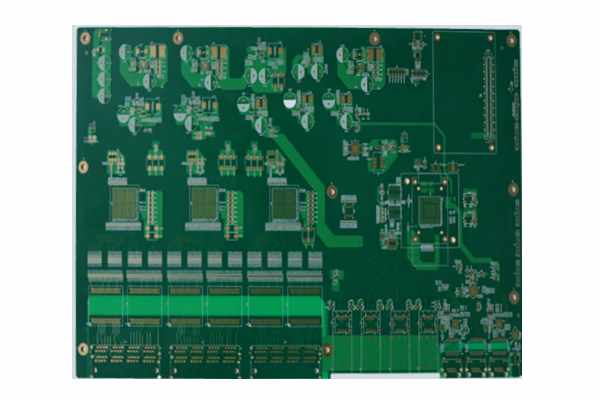

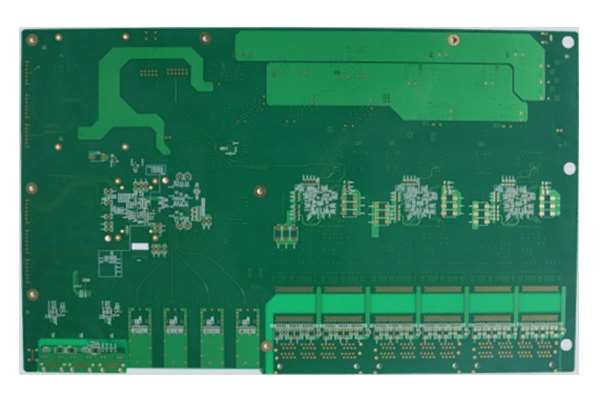

With the development of miniaturization and precision of electronic products, the PCB assembly manufacturing and assembly density used by electronic processing plants is getting higher and higher, the solder joints in circuit boards are getting smaller and smaller, and the mechanical, electrical and thermodynamic loads they carry are getting higher and higher. It is getting heavier and the requirements for stability are also increasing. However, the problem of PCB assembly solder joint failure will also be encountered in the actual processing process. It is necessary to analyze and find out the cause to avoid the solder joint failure from happening again.

So today, we will introduce to you the main reasons for the failure of PCB assembly processing solder joints.

The main reasons for the failure of PCB assembly processing solder joints:

1. Poor component pins: plating, pollution, oxidation, coplanarity.

2. Poor PCB pads: plating, pollution, oxidation, warpage.

3.Solder quality defects: composition, impurity substandard, oxidation.

4. Flux quality defects: low flux, high corrosion, low SIR.

5. Process parameter control defects: design, control, equipment.

6. Other auxiliary materials defects: adhesives, cleaning agent.

Methods of increasing the stability of PCB assembly solder joints:

The stability experiment of PCB assembly solder joints includes stability experiment and analysis.

On the one hand, its purpose is to evaluate and identify the stability level of PCB assembly integrated circuit devices, and to provide parameters for the stability design of the whole machine.

On the other hand, in the process of PCB assembly processing, it is necessary to improve the stability of solder joints. This requires the analysis of the failed product, to find out the failure mode, and to analyze the failure cause. The purpose is to revise and improve the design process, structural parameters, welding process, and improve the yield of PCB assembly processing. The failure mode of PCB assembly solder joints is the basis for predicting its cycle life and establishing its mathematical model.

In a word, We should improve the stability of solder joints and improve the yield of products.

PCBFuture is committed to supply high quality and economically One-Stop PCB assembly service to all world customers. For more information, please email to service@pcbfuture.com.

Post time: Oct-26-2022