The electronic components and electromechanical components have electrical contacts on the PCB, and the electrical connection between two discrete contacts is called interconnection. So what are the ways of PCB interconnection?

Welding method

This method has the advantages of simplicity, low cost and high reliability, and can avoid the failure caused by poor contact. The disadvantage is that it is inconvenient to exchange and maintain.

1. PCB wire welding

This method does not need any connectors, this method does not need any connectors, just use wires directly weld the external connection point on the PCB with the components outside the board.

2. PCB layout welding

The two PCB boards are connected by Flat cable connection, which is both reliable and not prone to connection errors.

3. Direct welding between PCBs

This method is often used for the connection between two printed boards with an included angle of 90 degrees.

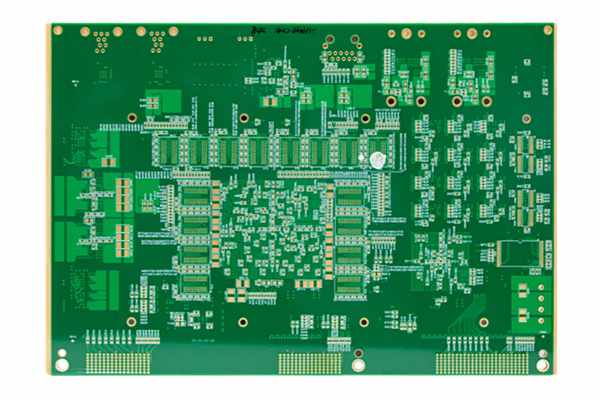

Plug and connector connection mode

In relatively complex instruments and equipment, plug connection is often used. It not only ensures the quality of mass production of products, reduces the cost of the system, but also provides convenience for debugging and maintenance.

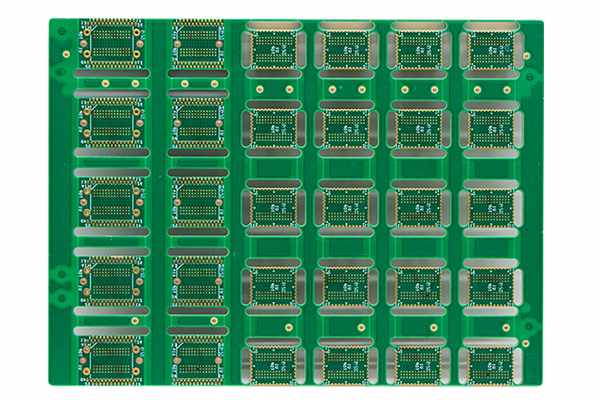

1. Printed board socket

This connection method is often used in complex instruments and equipment. This method is to make a printed plug from the edge of the PCB, and the plug part is designed according to the size of the socket, the number of connections, the contact distance, the position of the positioning hole, etc., so that it matches the special socket.

2. Standard pin connection

This method is used for external connection of PCB board. When connecting two PCBs through standard pins, they are generally in parallel or vertical state, which is easy to realize mass production.

PCBFuture has build our good reputation in the full turnkey PCB assembly service industry for prototype PCB assembly and low volume, mid volume PCB assembly. What our customers need to do is send the PCB design files and requirements to us, and we can take care of the rest of work. We are fully capable of offering unbeatable turnkey PCB services but keeping total cost within your budget.

If you looking for a ideal Turnkey PCB assembly manufacturer, please send your BOM files and PCB files to sales@pcbfuture.com. All your files are highly confidential. We will send you an accurate quote with lead time in 48 hours.

Post time: Feb-07-2023