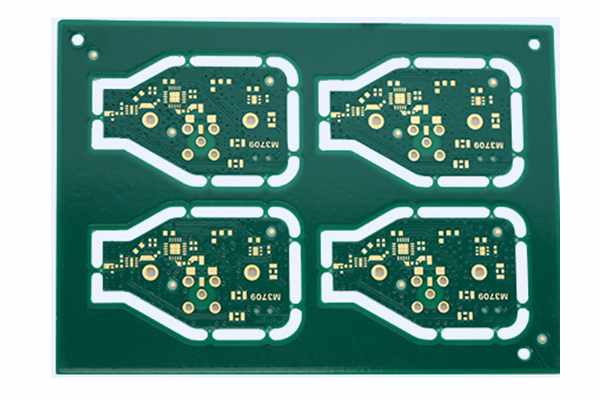

1. Cutting

Check the specification, model and cutting size of the substrate board according to the product processing or cutting specification drawings. The longitude and latitude direction, length and width dimension and perpendicularity of the substrate board are within the scope specified in the drawing.

2. Silk screen process printing

First, check whether the screen mesh, screen tension and film thickness meet the specified requirements.

Then, check the integrity of the figure, and there is no pinhole, notch or residual adhesive film. Check with the photographic original board, and the figure positioning size is consistent, and the line width, line spacing, connecting disk size or character marks are consistent.

3. Surface cleaning

The chemically cleaned PCB surface shall be free of oxidation and pollution, and shall be dry after cleaning.

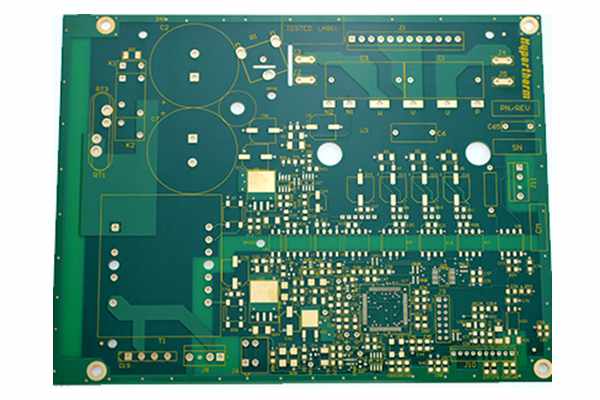

4. Circuit printing

Check the integrity of the circuit diagram, and there is no open circuit, pinhole, notch or short circuit. Check with the photographic original board, the figure positioning size is consistent, the line width and line distance are consistent, and the error is within the allowable range.

5. Etching

Check the integrity of the circuit diagram, and there is no open circuit, pinhole, notch or short circuit. Check with the photographic original board,and there is no etching (the line is too thin) or insufficient etching (the line is too thick).

6. Resistance welding

First of all, check the integrity of solder resist graphics, and there are no missing prints, pinholes, notches, ink seepage, hanging walls, and excess ink spots. It is consistent with the positioning size of the line figure, and the error is within the allowable range.

Secondly, check the curing degree of solder resist. The solder resist layer on the surface of copper conductor shall be tested with pencil, and the pencil hardness shall be more than 3H.

Third, check the bonding force of the solder resist. Stick and pull up the solder resist layer on the copper guide surface with adhesive tape. There should be no peeling solder resist on the tape.

7. Positive and negative character marks

Check the graphic integrity of character marks, and there are no missing printing, pinholes, notches or inking, hanging walls, and excess ink dots. It is consistent with the positioning size of the line graphics, the error is within the allowable range, and the character mark can be correctly recognized.

We have confidence in providing you the best combination of turn-key PCB assembly service, quality, price and delivery time in your Small batch volume PCB assembly order and Mid batch Volume PCB assembly order.

If you looking for a ideal PCB assembly manufacturer, please send your BOM files and PCB files to sales@pcbfuture.com. All your files are highly confidential. We will send you an accurate quote with lead time in 48 hours.

Post time: Dec-01-2022