How to check the failure components in PCB

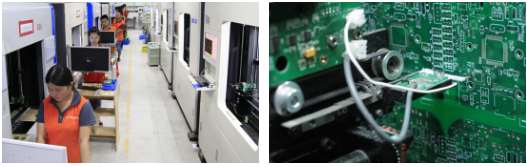

PCB fabrication and assembly is not difficult, the difficult is the how to inspect PCB after the production is completed.

Common PCB circuit board faults are mainly concentrated in the components, such as capacitors, resistors, inductors, diodes, triodes, FET chips and other integrated chips and crystal oscillators. The more intuitive way to judge the failure of these components can be observed through the eyes. There are obvious burning marks on the surface of electronic components. This kind of fault can be solved by directly replacing the problem components with new ones.

However, not all electronic components damage can be observed with the naked eye, Professional inspection tools are needed for inspection. The commonly used inspection tools include: multimeter, capacitance meter, etc. When it is detected that the voltage or current of an electronic component is not within the normal range, it indicates that there is a problem with the component or the previous component. We can try to replace it directly and check it again to see if it is normal.

Sometimes when we assemblying PCB, we will encounter the situation that the circuit board can’t work normally but can’t detect the problem. In this case, in many cases, the components are in the process of installation, due to the coordination of the various components, it may be due to unstable performance. In this case, we can try to judge the possible range of the fault according to the current and voltage, and try to narrow the fault area as much as possible. The only way is to try to replace the suspicious component until the problem component is found.

Since PCB circuit board is the foothold of components, the circuit board will definitely have faults. For example, due to the production process of tinning parts, there may be disconnection during the PCB corrosion process. In this case, if it is impossible to make up the wire, then it can only be solved with thin copper wire.

In a word, in the process of troubleshooting PCB components, we must pay attention to find out and solve the problem effectively.

PCBFuture can start at printed circuit board manufacturing, through to components supply and assembly. We are happy to supply boards and components. After the production is completed, we can provide professional PCB inspection to ensure the quality of the PCB. For more information, please email to service@pcbfuture.com.

Post time: Jun-19-2021