Customers often ask the PCBA factory when they are processing circuit board asssembly, do we need a dispensing process for our products? At this time, we will communicate with customers and judge whether to do the dispensing process according to the actual use scenarios of the customer’s products in the future. Let’s talk about what the dispensing process is and when it needs to be done.

1. What is the dispensing process?

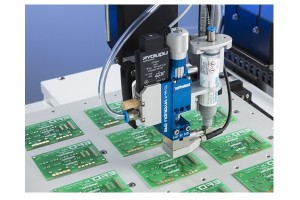

Dispensing is a process, also known as sizing, gluing, dripping, etc. It is the application, potting, and dripping of glue, oil or other liquids to the product, so that the product can be pasted and poured, sealing, insulating, fixing, smooth surface, etc. The dispensing process actually is a process to protect the product.

2. Why do the dispensing process?

The dispensing process has two major functions: preventing solder joints from loosening and moisture-proof insulation. Most of the places where the dispensing process is required are in areas of weak structure on the PCB, such as chips. When the product falls and vibrates, the PCB will vibrate back and forth, and the vibration will be transmitted to the solder joints between the chip and the PCB, which will crack the solder joints. At this time, dispensing does make the solder joints completely surrounded by glue, reducing the risk of cracking in the solder joints. Of course, not all PCBA will use the dispensing process, because its existence also brings some disadvantages, such as the complexity of the production process, and the difficulty of dismantling and repairing (it is difficult to remove the chip if it is stuck) .

Objectively speaking, dispensing will improve the product reliability, and it is responsible for the user. Not dispensing can reduce costs, and it is responsible for yourself. At the process level, dispensing is not a necessary option. It may not be done due to cost considerations. However, it is a good practice to improve product reliability and avoid quality problems. Whether to do dispensing or not depends on the actual use of the product.

Over the years, PCBFuture has accumulated a large number of PCB manufacturing, Production and debugging experience, and relying on these experiences, provide major scientific research institutes and large and medium-sized enterprise customers with a one-stop design, welding, and debugging of high-efficiency and high-reliability multi-layer printed boards from samples to batches.

If you have any questions or enquires, feel free to contact sales@pcbfuture.com , we will reply to you ASAP.

Post time: Mar-24-2022